FROM DESIGN TO INSTALLATION

PRE-CONTRACT ASSISTANCE

Bluesteel can be engaged in the project at a very early stage to develop design solutions side by side with architects and clients from the early conceptual stages. This collaboration is always beneficial and makes possible to:

- Plan each construction phase attentively.

- Foresee operational implications.

- Evaluate different technical solutions.

- Control and reduce costs.

DESIGN AND ENGINEERING

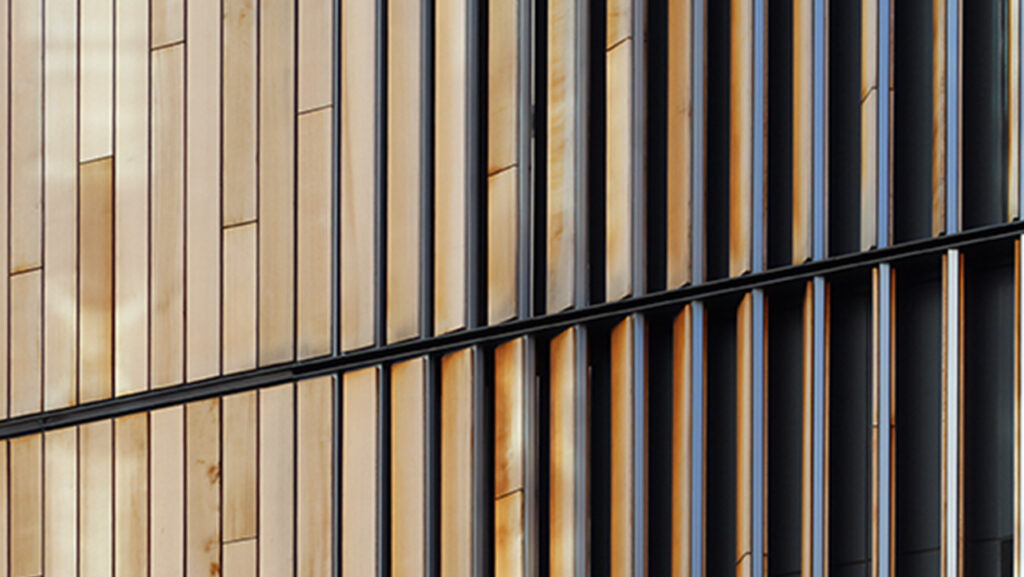

Developing effective technical solutions from the architectural concept to the fabrication drawings; this is our core activity, which is rooted in product industrialization. Our technical department can engineer any envelope system, devising tailor-made answers to any type of building.

QUALITY AND PROCUREMENT

Bluesteel complies to ISO 9001. We approach our day-to-day activities as growth opportunities and make every effort to monitor and evaluate the quality of both our products and our processes. Particular attention is given to a sustainable procurement because façades can bring a relevant contribution to the overall CO2 assessment in the building lifecycle.

DESIGN AND PROTOTYPES

Prototyping is fundamental to find the perfect balance between architectural choices and system functionality.

- A Visual mock-up (VMU) enables the project team to appreciate on a full-scale the material qualities of each architectural component and assess the final appearance of the façade.

- A Performance mock-up (PMU) is manufactured to certify façade performances, such as air tightness, water tightness and wind-load resistance, but often this analysis is extended to thermal properties, acoustics and impact loads.

FABRICATION

Ensuring high-quality standards depends mostly on a well organised and efficient fabrication environment. Bluesteel major plant in Colle Umberto involves:

- two CNC centres for profile machining.

- one semi-automated production line for curtain wall units assembling.

- one line for manufacturing and assembling items infills and decors (e.g. insulated panels, vents, fins…).

Bluesteel is part of Somec Gruppo since 2021 and can rely on synergies with other 20 Italian companies, such as being supported by the Fabbrica Works plant in San Biagio di Callalta, for a total unitized façade manufacturing capability of 30,000 sqm per year.

Bluesteel has been part of the Somec Group since 2021, as well as 20 other Italian companies with which new synergies are continuously implemented. Among these Bluesteel can count on the support of Fabbrica Works in San Biagio di Callalta (TV), with an aggregate annual production capacity of 30,000 m2.

PROJECT MANAGEMENT

Being able to manage situations effectively depends on a flexible attitude to project dynamics, which Bluesteel exceeds the basic implementation of a Quality Management System and ISO 45001 compliance thanks to its flexible and proactive approach. Each project is managed by a skilled team operating in a lean and efficient way. Our organization is particularly attentive to logistics since the very beginning of each project, as we believe that this activity is key to a timely delivery.

DELIVERY AND INSTALLATION

Our products are well protected with dedicated packaging, such as FSC timber crates or metal stillages. Goods are delivered to building site all over the world thanks to reliable shipping companies. A Bluesteel appointed site manager will be on site in order to supervise and coordinate installation activities, subcontracted to qualified personnel.

AFTER SALES AND MAINTENANCE

The cooperation between Bluesteel and clients goes on even after the project handover.

We are able to provide inspection and maintenance services to our products during the warranty duration period and during the building lifecycle.